Nearly 40 years of Excellence

For nearly 40 years, Matchless Plastics has stayed true to a simple mission: delivering reliable, high-quality plastic injection molding backed by exceptional service. What began as a small operation has grown into a trusted manufacturing partner serving industries nationwide.

Decade after decade, our commitment to innovation, adaptability, and customer success has built a reputation for precision, flexibility, and consistency. But our history is defined by more than the parts we produce, it’s defined by the long-term partnerships we’ve built and the trust we’ve earned along the way.

Expertise, Efficiency, and Excellence.

Every Step of the Way.

From short, tight turns to large-scale production runs, Matchless Plastics adapts to your unique project needs. We work with a broad range of materials and complex designs, offering quick turnaround times and the agility to handle last-minute changes without compromising quality.

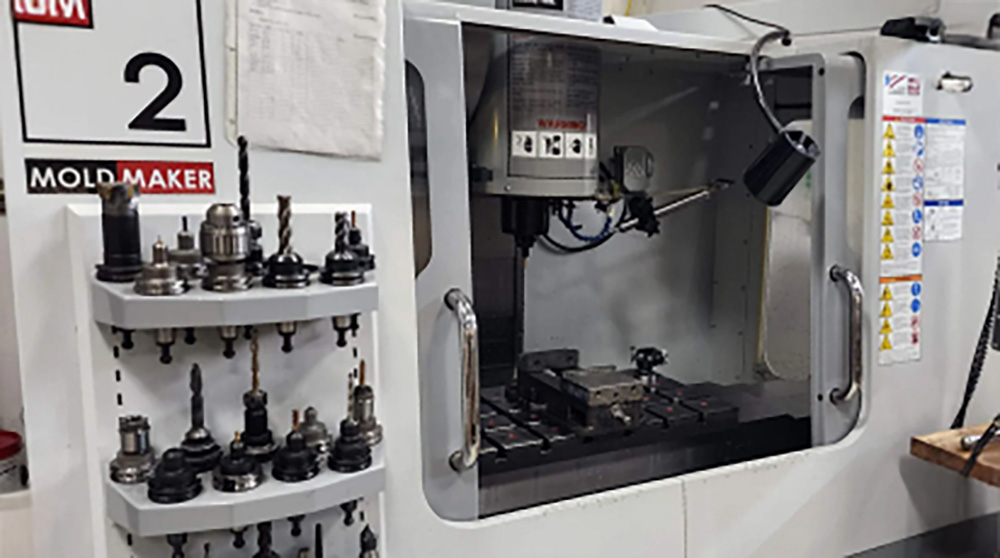

At Matchless Plastics, precision isn’t just a promise, it’s our standard. Our advanced injection molding technology and rigorous quality control ensure every part meets exact specifications with flawless consistency. When you choose us, you get unmatched accuracy, reliability, and confidence in every component.

Matchless delivers injection molded parts with unmatched precision and rigorous quality control. Our dedicated customer service team ensures a seamless experience, while our seasoned engineers bring the technical expertise needed to solve complex challenges. Together, we provide the accuracy, reliability, and support you can trust in every project.

Our Unique Process

Plastic injection molding is a manufacturing process where melted plastic resin is injected into a steel mold under pressure. Once the plastic cools and solidifies, the part is ejected and ready for use or secondary finishing. It’s ideal for consistent, repeatable parts at medium to high volumes.

We work with a wide range of engineering-grade resins, including ABS, PC, Nylon, Acetal, PEEK, TPE, TPU, and filled materials (glass, carbon, mineral). If your project has specific performance needs—strength, chemical resistance, heat tolerance—we’ll help select the right resin.

There are two main cost components:

- One-time tooling cost, typically $5,000–$50,000 depending on size and complexity

- Per-part cost, based on resin, cycle time, volume, and secondary operations

Higher volumes drive the cost per unit down. We often help customers optimize design to reduce both tooling and part cost.

Typical timelines:

- Design & DFM feedback: 1–2 weeks

- Tooling fabrication: 4–12 weeks depending on complexity

- Initial samples (T1): immediately after tool build

- Production-ready parts: often 3-4 weeks after approval

We offer expedited tooling for time-sensitive projects.

We work with customers at every stage; from rough concepts to production-ready 3D models. Our engineers can:

- Suggest design improvements (DFM)

- Reduce part weight

- Improve moldability

- Eliminate unnecessary cost

If you’re still iterating, we’ll help you get to a manufacturable design faster.